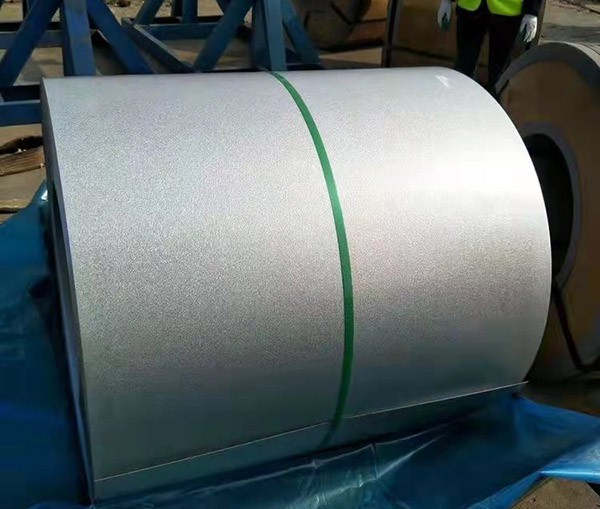

Aluminum magnesium galvanized sheet is a type of metal sheet with excellent performance,and its manufacturing process by

aluminum magnesium galvanized sheet manufacturer involves multiple technologies and steps.Here are some detailed information about the manufacturing process of this product:

1.Substrate preparation

Firstly,it is necessary to prepare a suitable substrate,usually an iron substrate.The selection of substrate is crucial for the performance of the product.The substrate needs to undergo processes such as cleaning and acid washing to remove surface impurities and oxides,ensuring that the coating can firmly adhere.

2.Composition of coating

The coating of aluminum magnesium galvanized sheet is composed of various alloy elements such as zinc,aluminum,magnesium,etc.The proportion and types of these elements directly affect the performance of the product.

3.Hot dip galvanizing process

Hot dip galvanizing is one of the key steps for manufacturers of aluminum magnesium galvanized sheets.According to different pre-treatment methods,hot-dip galvanizing can be divided into flux hot-dip galvanizing and hydrogen reduction hot-dip galvanizing.The flux method is mainly used for steel components,steel pipes,steel profiles,etc.,while the hydrogen reduction method is commonly used for continuous hot-dip galvanizing of steel strips,steel wires,etc.

3.1 Flux based hot-dip galvanizing

In the process of hot-dip galvanizing using flux method,the substrate is immersed in a zinc solution containing flux,which helps to improve the fluidity of the zinc solution and the quality of the coating.This method is applicable to various complex shaped components.

3.2 Hydrogen reduction method for hot-dip galvanizing

Hydrogen reduction hot-dip galvanizing is commonly used for continuous production of steel strips and wires.In this process,the substrate passes through a tank containing zinc liquid and forms a coating under the reduction effect of hydrogen gas.The advantage of this method is that aluminum magnesium galvanized sheet manufacturers can achieve high-speed continuous production.

4.Coating control

In the actual production process,enterprises will adjust the composition and thickness of the coating according to their own needs.For example,aluminum magnesium galvanized sheet manufacturers can optimize the corrosion resistance and mechanical properties of their products by controlling the content of aluminum and magnesium.In addition,the thickness of the coating is also an important parameter,which directly affects the service life and performance of the product.

In short,the manufacturing process of aluminum magnesium galvanized sheet manufacturers is a complex process involving multiple links such as substrate preparation and hot-dip galvanizing process.Through scientific and reasonable process design and strict quality control,high-performance aluminum magnesium galvanized sheet can be produced to meet various application needs.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com