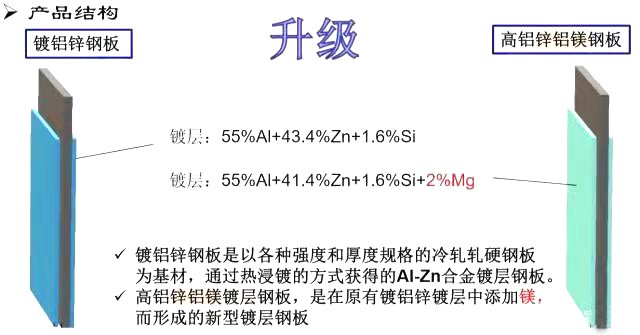

Aluminum zinc plating:

Hot dip aluminum zinc steel plate is a coated steel plate obtained by double-sided hot-dip aluminum zinc alloy coating on cold-rolled steel plate as the substrate. The alloy composition of the coating is 55% Al, 43.5% Zn, and 1.5% Si by mass.

2. Galvanized aluminum magnesium:

The coating obtained by immersing pre treated steel strip into molten zinc containing aluminum and magnesium on a hot-dip galvanizing production line.

The composition of the alloy coating is as follows:

① Magnesium content is 1.0~2.0%, aluminum content is 0.8~3.0%

② Magnesium content is 3%, aluminum content is 11%

2、 Product Features

1. Aluminum zinc plating

Hot dip coating of 100-200g/m2 of 55% AlZn protective layer on steel substrate, the corrosion resistance is mainly due to the protective function of aluminum. When zinc is worn, aluminum forms a dense layer of alumina, preventing further corrosion of the interior by corrosion-resistant substances. Weak alkali corrosion resistance; The protection period is 8-15 years.

2. Galvanized aluminum magnesium

The main component is 3% Mg-11% Al Zn, which has strong resistance to chlorine (salt/sweat/seawater/sea breeze/soil) and alkali corrosion. It has self-healing function and can guarantee 20-30 years without red rust.

3、 Characteristics of galvanized aluminum magnesium products

1. Alloy elements such as Al, Mg, and Si are added to the coating of hot-dip galvanized aluminum magnesium steel plate, greatly improving the corrosion inhibition effect of the coating. Compared with ordinary galvanized products, the coating has less adhesion but can achieve better corrosion resistance, which is 10-20 times that of hot-dip galvanized steel plate.

2. The coating components around the cutting surface continuously dissolve, forming a dense protective film mainly composed of zinc hydroxide, alkaline zinc chloride, and magnesium hydroxide. This protective film has low conductivity and has a suppressive effect on the corrosion of the cutting surface.

3. Due to its super corrosion resistance reaching 10-20 times that of ordinary hot-dip galvanized steel plates and the self-healing effect of corrosion-resistant cutting surfaces, components made of hot-dip galvanized aluminum magnesium steel plate alloy coating will naturally have a long service life, generally exceeding 30 years.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com