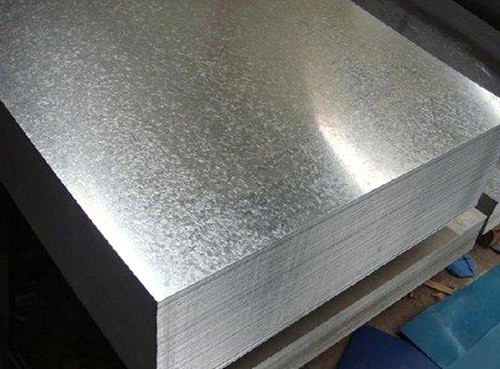

Galvanized aluminum coil is a new type of material that has emerged in China in recent years due to its application, commonly referred to as CCLI. It is a product made from aluminum zinc coated steel plates (55% aluminum, 43% zinc, and 1.6% silicon) that have better corrosion resistance than galvanized steel plates. After surface degreasing, phosphating, and complex acid salt treatment, they are coated with organic coatings and baked.

Coating type

1. Regular modified polyester (RMP)

2. Ever Clean or Self Clean

3. Silicon modified polyester (SMP)

4. Hi Durable Polyester (HDP)

5. Fluorocarbon (PVDF)

Coating structure

2/1M two coats and one baking

2/2M two coat two bake

characteristic:

The following is an example of products in practical applications:

Substrate selection: AZ150 (aluminum zinc content 150g/m2;) G345A high-strength aluminum zinc plated sheet (55% aluminum, 43% zinc, and 1.6% silicon)

Corrosion resistance data: 5% NaCl at 35 ℃, 1000Hrs, good field, Scribe No Blister below 2mm

Q. At U.V: 2000hours, color difference MAX.2, light retention rate of over 90%

The above data indicates that aluminum zinc plated steel plates (AZ150, G345A, PVDF) are highly suitable for construction or other facilities in end environments, with corrosion resistance and weather resistance. Moreover, major steel mills can guarantee a service life of over 20 years for this type of steel plate. In addition, high-strength steel plates have been widely used abroad and have good economic benefits, which is also a development trend in China.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com