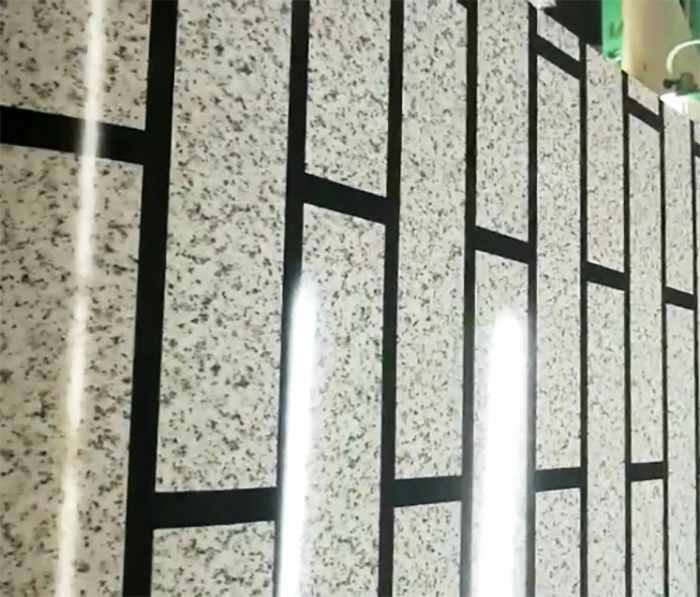

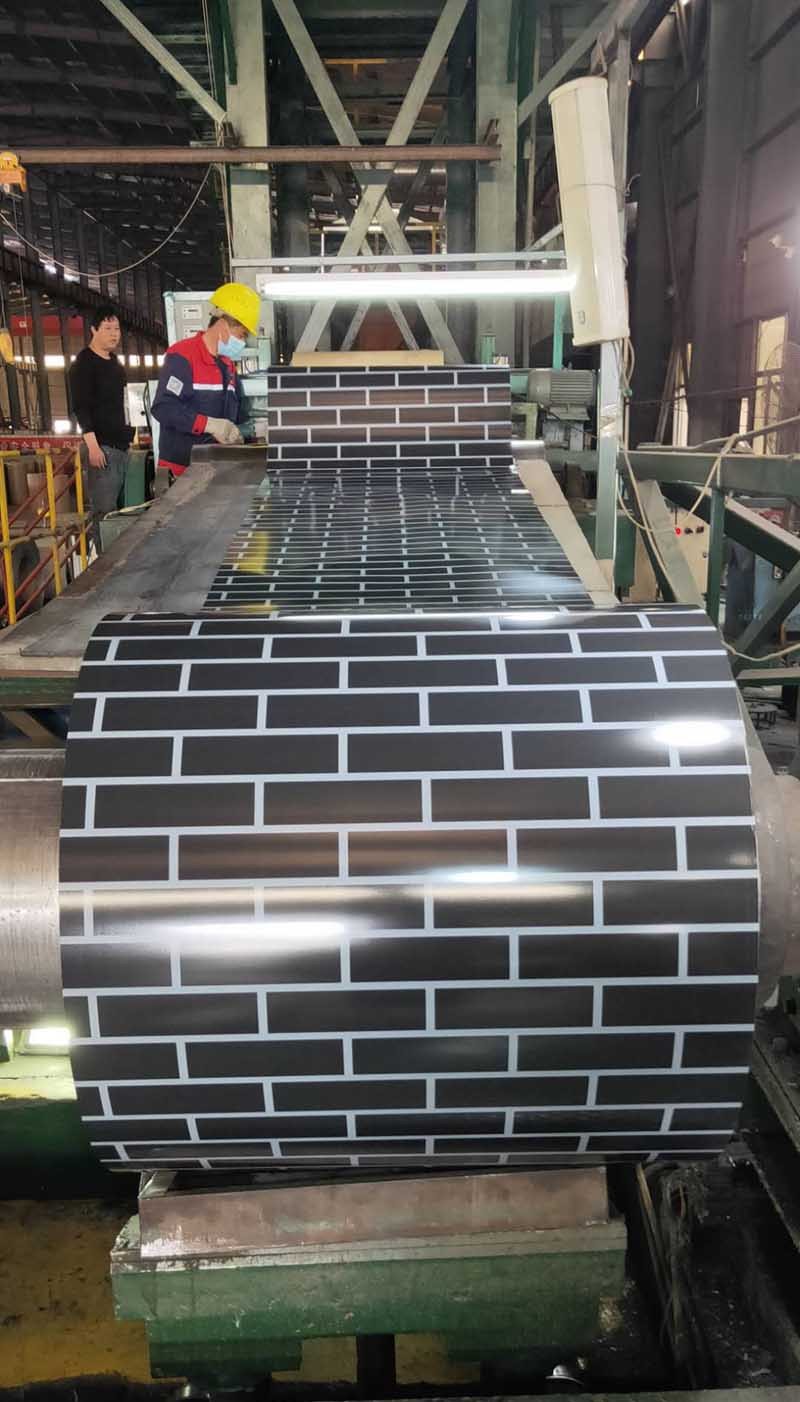

Printed plate, also known as printed color steel plate It refers to the process of printing various patterns on steel plates through technical means based on various substrates

Printed boards can be applied to household appliances, furniture, doors and windows, signage, outdoor decoration, etc

Primer types and film thickness: Primers are divided into four categories: epoxy resin, polyester resin, acrylic resin, and polyurethane resin. Generally, the primer is selected based on the product's intended use, application, processing level, and the matching of the topcoat. The film thickness of the primer is usually 5um.

1. Epoxy primer

Good adhesion to the substrate, water resistance, alkali resistance, and chemical corrosion resistance, it is an early primer for coil materials, and its flexibility is not as good as other primers.

2. Polyester base

Good adhesion to the substrate, excellent flexibility, sensitive to humid environments, and less chemical resistance than epoxy primer.

3. Water soluble acrylic primer

Good adhesion to the substrate, excellent flexibility, low organic solvent content, low-temperature curing, unsuitable for storage in humid environments, high pre-treatment requirements.

4. Polyurethane primer

Has chemical resistance, friction resistance, durability, and good flexibility.

Type and film thickness of topcoat

Common topcoats include polyester, silicon modified polyester, polyvinyl chloride plastic sol, and polyvinylidene fluoride.

1. Polyester

Good adhesion, wide range in formability and outdoor durability, moderate chemical resistance.

2. Silicon modified polyester

The hardness, wear resistance, and heat resistance of the coating are good, as well as good outdoor durability and non powdering, limited gloss retention and flexibility, and moderate to high cost.

3. Polyvinylidene chloride

It has good formability and color retention, excellent outdoor durability and anti powdering, anti solvent properties, limited color, and high price.

4. Polyvinyl chloride plastic sol

Excellent external durability, chemical resistance, damage resistance, aesthetics, requiring special primer matching. The surface can have a smooth shape, used for pressing or automatic shrinkage to form patterns. The coating thickness is generally greater than 100um. Except for plastic sol, in general, the coating thickness of primer and topcoat is>=20um, and the product's various properties can achieve the predetermined goals.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com